Medhat group is the leading manufacturer for formwork and scaffolding in the region, this leadership has made Medhat to integrate its production from zero to 100 in this industry.

That is why product casting is a must for Medhat group in order to minimize the challenges and maximize the group capability in supporting developers, contractors and distributors in the region.

Click to visit casting product

Casting is very important for Medhat Group, because it plays a vital role in producing complex components for formwork and scaffolding with intricate details and precise dimensions. It also supports other products manufacturing, and the growth of the overall economy in this industry.

Supply chain in formwork industry has been integrated by Medhat Group and its affiliate companies in order to create competitive advantages in supporting the construction and infrastructure industry in the region.

Solvent casting is a technique used to create scaffolds for tissue engineering. This method allows for the processing of both synthetic and natural biomaterials into scaffolds. These scaffolds are crucial in tissue engineering as they provide a 3D structure that supports cell growth and tissue regeneration.

The product casting in Medhat Group

The casting line has been opened in order to fulfill the technical and engineering department requirement for design and manufacturing of scaffolding, Concrete formwork and latest systems in this industry including but not limited to Rail Climbing System, Shario System & Tunnel Form work

The casting Products for Scaffolding & Formwork:

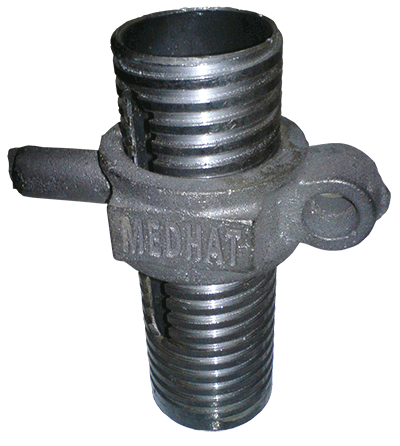

- Tie Rod Wing Nut Anchor Nut for Construction Concrete

- Coupler & Clamp

- Single & Double Coupler

Click to visit casting product

Metal casting offers several advantages, including material conservation, the ability to create intricate designs, suitability for small production runs, and cost-effectiveness. The process utilizes low-cost materials like scrap metal and allows for the production of complex shapes due to the molten metal’s ability to flow into intricate mold cavities.